Exploring the Benefits of Vertical Packaging Machines for Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, vertical packaging machines have emerged as indispensable assets for enhancing efficiency and productivity. According to a report by Smithers Pira, the global market for packaging machinery is projected to reach $45 billion by 2025, driven by the increasing demand for innovative packaging solutions. Vertical packaging machines, specifically, are recognized for their ability to optimize floor space while providing higher speed and precision in packaging processes. In fact, a study by Freedonia Group reveals that the adoption of advanced packaging technologies, including vertical systems, can improve operational efficiency by up to 30%. As manufacturers strive to meet consumer demands for sustainability and convenience, the vertical packaging machine stands out, offering significant benefits such as reduced material waste, enhanced product protection, and streamlined production lines, thus reshaping the future of the packaging industry.

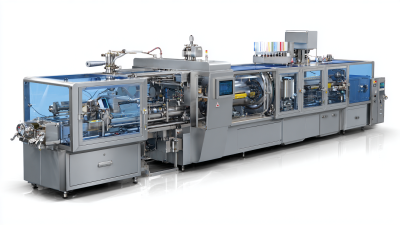

Understanding Vertical Packaging Machines and Their Role in Manufacturing

Vertical packaging machines have become an indispensable component of modern manufacturing, especially in industries like food and pharmaceuticals. These machines utilize a vertical form-fill-seal (VFFS) process that efficiently packages products in a variety of forms, including powders, granules, and liquids. According to a recent report by MarketsandMarkets, the global vertical packaging market is expected to grow from USD 3.4 billion in 2021 to USD 5.1 billion by 2026, reflecting a compound annual growth rate (CAGR) of 8.5%. This growth is attributed to the increasing demand for automation and the need for high-efficiency packing solutions.

The role of vertical packaging machines in manufacturing extends beyond mere packaging. They significantly enhance production speed and reduce labor costs while minimizing material waste. A study by Smithers Pira indicated that automated packaging solutions can lead to a 30-50% reduction in overall packaging costs. Additionally, these machines are designed for versatility, allowing manufacturers to easily switch between different product sizes and formats without extensive downtime. As sustainability continues to be a priority in manufacturing, vertical packaging machines also support eco-friendly practices by enabling the use of thinner, recyclable packaging materials, further aligning with the industry's shift towards greener solutions.

Key Advantages of Implementing Vertical Packaging in Production Lines

Vertical packaging machines have emerged as a vital asset in modern manufacturing, streamlining processes and enhancing efficiency within production lines. One of the key advantages is their ability to maximize floor space. By operating in a vertical orientation, these machines require significantly less horizontal space compared to traditional horizontal systems, allowing manufacturers to utilize their facilities more effectively and accommodate additional production equipment.

Moreover, vertical packaging machines typically offer faster packing speeds, which can lead to increased output rates. Their design allows for precise filling and sealing in a compact timeframe, resulting in higher productivity. This efficiency not only aids in meeting consumer demands but also minimizes labor costs, as fewer operators are required to manage the packing process. Additionally, with advancements in technology, these machines can incorporate smart features for better quality control, reducing the likelihood of errors and ensuring consistent product packaging that meets industry standards.

Factors to Consider When Choosing a Vertical Packaging Machine

When selecting a vertical packaging machine, manufacturers need to consider several key factors that can significantly impact their operational efficiency and product quality. One important aspect is the machine's capability to handle various packaging materials and sizes. As the food packaging equipment market continues to grow, projected to reach $28.29 billion by 2032, it's vital for companies to invest in machines that can adapt to evolving packaging needs while ensuring durability and reliability.

Another factor to consider is the machine’s automation level and ease of integration into existing production lines. With the increasing shift towards automation in response to labor shortages and the need for efficiency, a vertical packaging machine that seamlessly integrates with other automated systems can improve overall productivity. Furthermore, considering the machine's maintenance requirements and availability of technical support can prevent potential downtimes, enhancing long-term operational success. As the market for vertical packing solutions continues to expand, understanding these critical factors will aid manufacturers in making informed decisions that align with their growth strategies.

Best Practices for Optimizing Vertical Packaging Processes

In the modern manufacturing landscape, optimizing vertical packaging processes is paramount for enhancing efficiency and reducing operational costs. Recent industry reports indicate that vertical packaging machines can significantly boost productivity by up to 30% compared to traditional horizontal systems. Because these machines allow for compact designs and faster operation, they are becoming increasingly popular among manufacturers seeking to streamline their packaging lines.

Tips: To maximize the benefits of vertical packaging machines, regularly train staff on best practices for machine operation and maintenance. This not only ensures optimal performance but also prolongs the lifespan of the equipment. Moreover, integrating automation technologies within vertical packaging processes can further enhance efficiency, accommodating the growing demand for quick turnaround times in production.

Furthermore, recent movements in automation, such as the acquisition of a leading technology firm, underscore the industry's shift toward incorporating advanced solutions in packaging operations. By investing in innovative vertical packaging systems, manufacturers can remain competitive and agile in a fast-paced market, ultimately driving higher profits and customer satisfaction.

Tips: Consider conducting periodic assessments of your packaging processes to identify bottlenecks or areas for improvement. Utilizing data analytics can provide insights into workflow efficiencies and help refine the vertical packaging strategy effectively.

Future Trends in Vertical Packaging Technology for Manufacturers

The future of vertical packaging technology is poised for significant advancements, driven by the increasing demand for efficiency and sustainability in modern manufacturing. With the global parsley market projected to reach $6.08 billion by 2024 and an impressive CAGR of 5.09% from 2024 to 2033, manufacturers are urged to adopt innovative packaging solutions that can keep pace with this growth. Vertical packaging machines have emerged as a vital asset for businesses aiming to streamline operations and reduce waste.

As advanced packaging technologies continue to evolve, manufacturers in mainland China are experiencing a remarkable rebound in the packaging industry. The surge in demand for integrated circuits, fueled by the rapid deployment of 5G networks and the electric vehicle market, is pushing manufacturers to incorporate state-of-the-art vertical packaging systems. These systems not only enhance production efficiency but also contribute to a greener operation by minimizing material usage and recycling opportunities. The ongoing transformation in vertical packaging technology is set to redefine best practices across various sectors, helping manufacturers meet both consumer needs and environmental standards.

Exploring the Benefits of Vertical Packaging Machines for Modern Manufacturing - Future Trends in Vertical Packaging Technology for Manufacturers

| Feature | Description | Benefits | Future Trends |

|---|---|---|---|

| Speed | High-speed packaging systems capable of processing large volumes. | Increased production efficiency and reduced labor costs. | Integration with IoT for real-time monitoring and optimizations. |

| Versatility | Ability to package various products, from solids to liquids. | Flexibility to adapt to different product lines without significant downtime. | Development of machines that can handle new materials and shapes. |

| Accuracy | Precision in filling and sealing packages to minimize waste. | Reduction in product loss and enhanced quality control. | Advancements in sensor technology to improve accuracy further. |

| Sustainability | Use of eco-friendly materials and reduced energy consumption. | Lowers environmental impact and aligns with consumer preferences. | Innovation in biodegradable packaging solutions. |

| Cost-effectiveness | Reduction in packaging costs through efficient design and operations. | Improved profit margins and competitive pricing. | Dynamic pricing models based on real-time data analysis. |

Related Posts

-

Exploring Industry Growth: Vertical Form Fill Seal Machines at the 138th Canton Fair 2025

-

Essential Food Packing Machine Checklist: 10 Key Factors for Optimal Performance

-

20 Best Innovations in Wrapping Machines You Need to Know

-

Innovative Pouching Machine Designs Transforming Packaging Solutions

-

How to Choose the Right Form Fill and Seal Machine for Your Packaging Needs

-

Discover the Future of Packaging: How Horizontal Form Fill Seal Machines Revolutionize Efficiency