Discover the Future of Packaging: How Horizontal Form Fill Seal Machines Revolutionize Efficiency

The packaging industry is undergoing a significant transformation thanks to the advent of horizontal form fill seal machines, which are revolutionizing efficiency across various sectors. According to a report by MarketsandMarkets, the global market for form fill seal machines is projected to grow from USD 7.5 billion in 2020 to USD 10.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.3%. These machines streamline the packaging process by allowing for faster production speeds and enhanced precision, ultimately reducing labor costs and waste. With capabilities to package a wide range of products—from food items to pharmaceuticals—horizontal form fill seal machines are proving essential for manufacturers looking to improve operational efficiency and meet the increasing demands of consumers for sustainability and rapid delivery. The integration of advanced technology in these machines not only boosts productivity but also aligns with the industry's shift towards more automated and environmentally friendly packaging solutions.

Understanding the Basics of Horizontal Form Fill Seal Machines

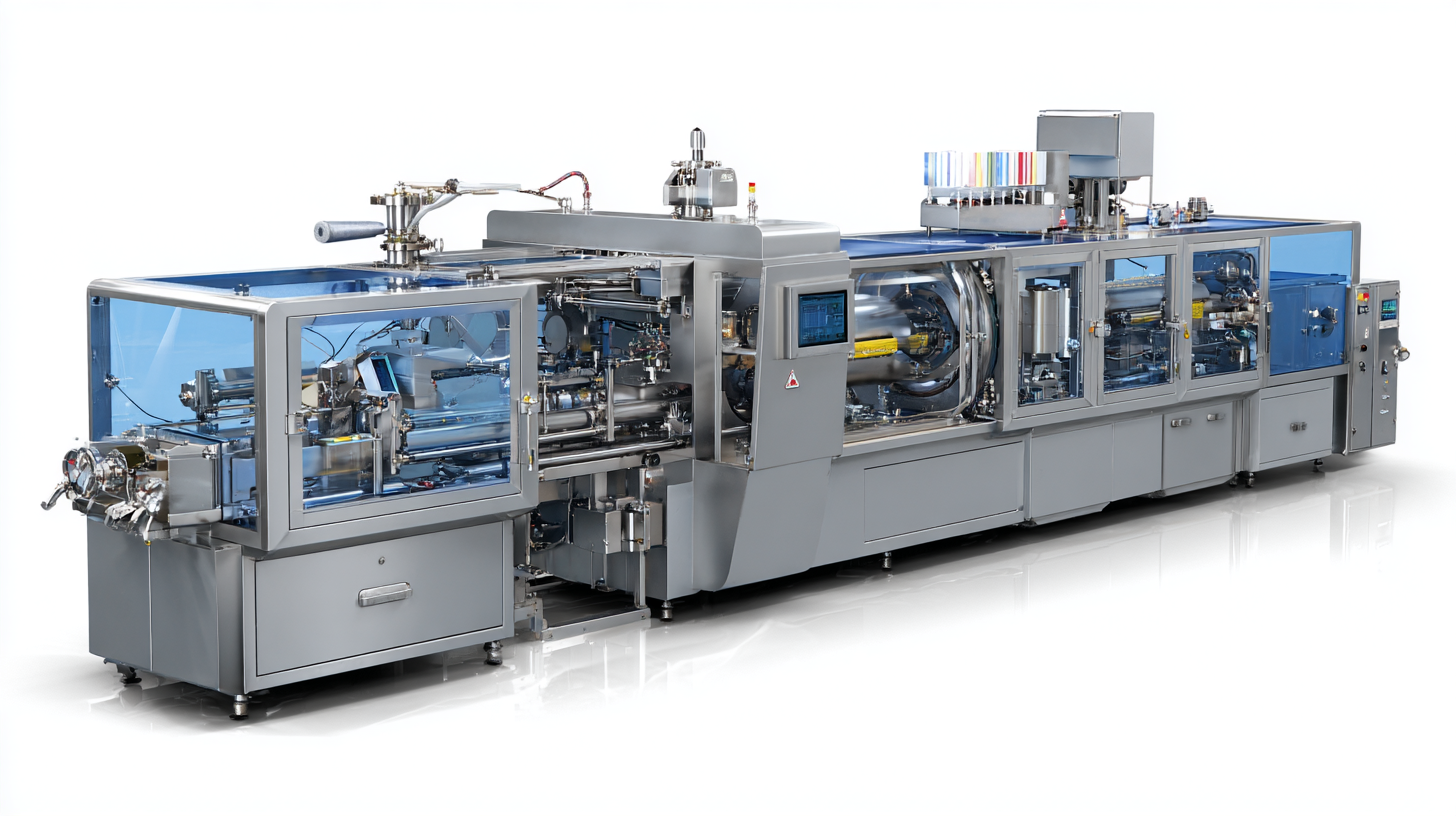

Horizontal Form Fill Seal (HFFS) machines are at the forefront of packaging innovation, streamlining production while enhancing efficiency across industries. Unlike traditional packaging methods, HFFS technology automates the entire process of forming, filling, and sealing pouches in one continuous motion. This not only reduces labor costs but also minimizes material waste. According to a recent report by Grand View Research, the global market for HFFS machines is expected to reach USD 1.78 billion by 2025, driven by increasing consumer demand for quick-service food products and convenient packaging solutions.

One of the most significant advantages of HFFS machines is their versatility. They can handle a wide range of products, from liquid to solid, in varying pouch sizes and shapes. This aligns with data from Smithers Pira, which indicates that flexible packaging is projected to grow at a rate of 4.4% annually, outpacing rigid packaging. Moreover, the technological advancements such as servo-driven controls and advanced sensors have improved speed and accuracy, achieving up to 200 packages per minute. This leap in technology allows manufacturers to meet high-volume production demands while ensuring quality and consistency, ultimately shaping the future of packaging.

Key Advantages of Using Horizontal Form Fill Seal Technology

Horizontal Form Fill Seal (HFFS) technology has become a game changer in packaging, particularly in industries such as food and pharmaceuticals. The key advantages of using HFFS machines include enhanced efficiency, cost savings, and improved product protection. According to a report by Smithers Pira, the demand for flexible packaging is expected to grow at a CAGR of 4.8% from 2020 to 2025, highlighting the increasing reliance on innovative packaging solutions. HFFS machines contribute to this trend by reducing production time through streamlined processes, allowing manufacturers to achieve over 95% efficiency in filling and sealing operations.

Another significant advantage of HFFS technology is the adaptability it offers. These machines can handle a wide range of materials, and they can easily switch between different package sizes and styles without extensive downtime. A study by MarketsandMarkets indicates that the HFFS packaging market is projected to reach $8.2 billion by 2025, driven by its ability to meet diverse consumer demands while maintaining high-speed production. This versatility not only reduces wastage but also improves sustainability, aligning with the industry's growing focus on eco-friendly practices.

Step-by-Step Guide to Implementing HFFS Machines in Your Facility

Implementing Horizontal Form Fill Seal (HFFS) machines in your facility marks a pivotal step towards enhancing operational efficiency and product integrity. According to a report by MarketsandMarkets, the global packaging equipment market is projected to reach USD 47.9 billion by 2025, highlighting the critical role of advanced machinery like HFFS. These machines not only streamline the packaging process by combining forming, filling, and sealing into one cohesive system but also reduce material waste by utilizing precise measurements.

To successfully integrate HFFS machines, start with a thorough analysis of your current packaging workflows. Evaluate the specific needs of your production line and identify the types of products that would benefit most from HFFS technology. A study by PMMI reveals that companies see up to a 30% increase in production speed after adopting HFFS systems. Follow this analysis with a careful selection process, ensuring that the chosen machine aligns with your operational goals. Additionally, training your staff on the new system will be essential for maximizing its potential, as human expertise remains a crucial factor in leveraging technological advancements in packaging.

Efficiency Gains from Implementing Horizontal Form Fill Seal Machines

This chart illustrates the efficiency gains from implementing Horizontal Form Fill Seal (HFFS) machines. As shown, efficiency improved from 65% before HFFS implementation to 90% after, highlighting the significant impact of adopting this technology in packaging operations.

Maximizing Efficiency with HFFS: Best Practices for Operation

Horizontal Form Fill Seal (HFFS) machines are a game-changer in the packaging industry, particularly due to their ability to streamline production and enhance efficiency. According to a report from MarketsandMarkets, the global HFFS market is expected to reach $7.32 billion by 2025, growing at a CAGR of 5.4%. This growth reflects the increasing demand for flexible and efficient packaging solutions across various sectors including food, beverage, pharmaceuticals, and personal care products.

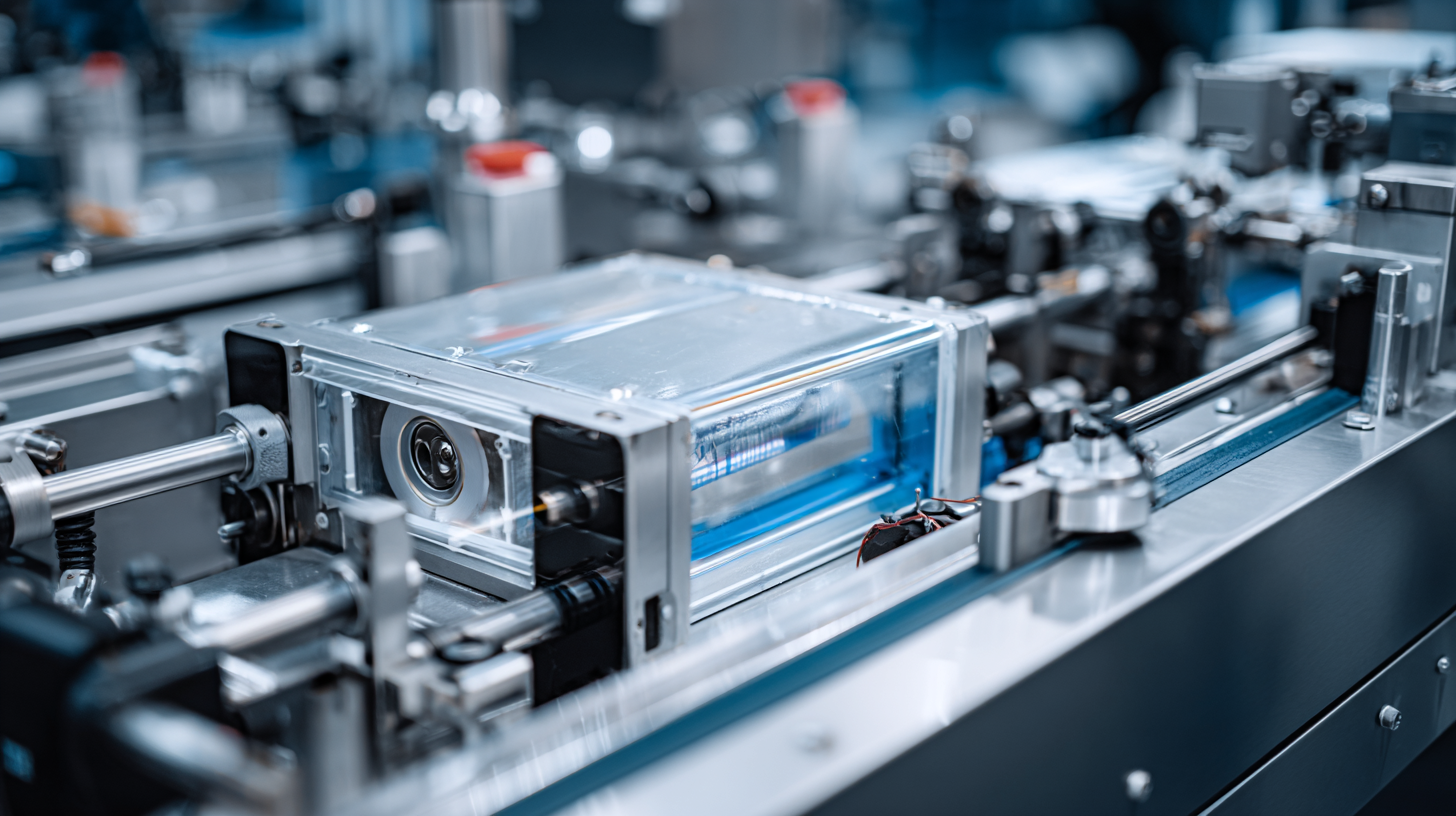

To maximize efficiency when operating HFFS machines, several best practices should be followed. Firstly, ensuring optimal machine settings based on the specific packaging material can significantly reduce waste and downtime. The use of high-quality materials is crucial; for instance, using polyethylene films helps maintain seal integrity and minimizes the risk of product spoilage. Additionally, regular maintenance checks can enhance machine reliability and extend its lifecycle, further contributing to overall operational efficiency. A report by the Packaging Machinery Manufacturers Institute highlights that companies employing preventive maintenance can reduce unplanned downtime by as much as 30%, enhancing their competitiveness in the market.

Future Innovations in Horizontal Form Fill Seal Technology and Their Impact

The landscape of packaging technology is undergoing a significant transformation, particularly with the advancements in horizontal form fill seal (HFFS) machines. These innovations not only streamline the packaging process but also enhance the overall efficiency and sustainability of production lines. HFFS machines are now equipped with sophisticated sensors and control systems that optimize speed and reduce material waste, allowing manufacturers to achieve higher productivity while minimizing their environmental footprint.

Moreover, the future of HFFS technology is poised to integrate more smart features, such as real-time monitoring and predictive maintenance capabilities. This shift towards automation and intelligent systems will empower manufacturers to respond more swiftly to market demands and operational challenges. Enhanced data analytics will provide insights into performance, allowing for continuous improvements in packaging operations. As these innovations unfold, the impact on the packaging industry will be profound, ensuring that businesses remain competitive in an increasingly fast-paced market.

Related Posts

-

How to Choose the Right Form Fill and Seal Machine for Your Packaging Needs

-

Exploring Industry Growth: Vertical Form Fill Seal Machines at the 138th Canton Fair 2025

-

The Ultimate Guide to Comparing Packaging Automation Solutions for Global Buyers

-

Essential Food Packing Machine Checklist: 10 Key Factors for Optimal Performance

-

5 Best Horizontal Form Fill Seal Machines for Your Packaging Needs

-

Innovative Pouching Machine Designs Transforming Packaging Solutions