Discover the Ultimate Guide to Choosing the Best Seal Machine for Your Needs

Choosing the right seal machine is crucial for businesses aiming to enhance efficiency and product integrity in packaging. According to industry reports, the global packaging machinery market was valued at over $45 billion in 2020 and is projected to grow significantly, driven by increasing demand for packaged goods. Seal machines play a vital role in this growth, ensuring that products are securely packaged to maintain freshness and prevent contamination. With a wide variety of seal machines available, from manual to fully automated systems, it is essential to understand the specific needs of your operation to make an informed decision. This guide will help you navigate the complexities of choosing the best seal machine tailored to your requirements, maximizing both productivity and operational effectiveness.

Understanding Different Types of Seal Machines: A Comprehensive Breakdown of Technology Options

When considering different types of seal machines, understanding the underlying technology is crucial. Seal machines vary significantly in their mechanisms, from simple manual devices to advanced automated systems. Each type of machine serves specific needs, whether for packaging food, pharmaceuticals, or industrial products. The technology behind these machines often determines their efficiency, speed, and seal integrity, which are essential factors in maintaining product quality.

One significant aspect is heat sealing, a process commonly used in flexible food packaging. This method relies on precise temperature control and pressure to create strong, airtight seals that protect contents from contamination and spoilage. Various factors, such as material properties and environmental conditions, can influence seal integrity, making it vital for users to select a machine that aligns with their specific requirements. Understanding these technological differences can help consumers make informed choices when selecting a seal machine that meets their unique needs.

Discover the Ultimate Guide to Choosing the Best Seal Machine for Your Needs

| Type of Seal Machine | Key Features | Best Use Case | Price Range |

|---|---|---|---|

| Vacuum Seal Machine | Removes air, airtight seal, ideal for food | Home food storage, meal prep | $50 - $300 |

| Impuse Seal Machine | Quick heat seal, adjustable temperature | Light industrial use, plastic bags | $75 - $500 |

| Continuous Seal Machine | Consistent sealing process, high speed | Mass product sealing, larger operations | $200 - $2000 |

| Handheld Seal Machine | Portable, battery-operated, easy to use | Travel use, occasional sealing | $20 - $100 |

| Chamber Seal Machine | Seals bags in a chamber, better for liquids | Commercial kitchens, liquid food sealing | $300 - $3000 |

Key Factors to Consider When Choosing the Right Seal Machine for Your Business Needs

When choosing the right seal machine for your business needs, there are several key factors to consider to ensure you make an informed decision. First and foremost, assess the scale at which you operate. The global vacuum sealing machine market is projected to grow from $4.71 billion in 2023 to $7.2 billion by 2032, indicating a significant increase in demand across various sectors. This growth spurt highlights the importance of selecting a machine that can keep pace with your production needs.

Another crucial aspect to consider is the machine’s efficiency and ease of use. Look for models that offer features such as adjustable sealing times and temperatures, which can enhance the versatility of your sealing process. Additionally, consider the machine's maintenance requirements and warranty options, as these can impact long-term operational costs.

Tips:

- Evaluate the materials you’ll be sealing: Different machines perform better with specific materials, so choose one tailored to your needs.

- Consider automation levels: Depending on your production scale, selecting a semi-automatic or fully automatic machine can improve efficiency and reduce labor costs.

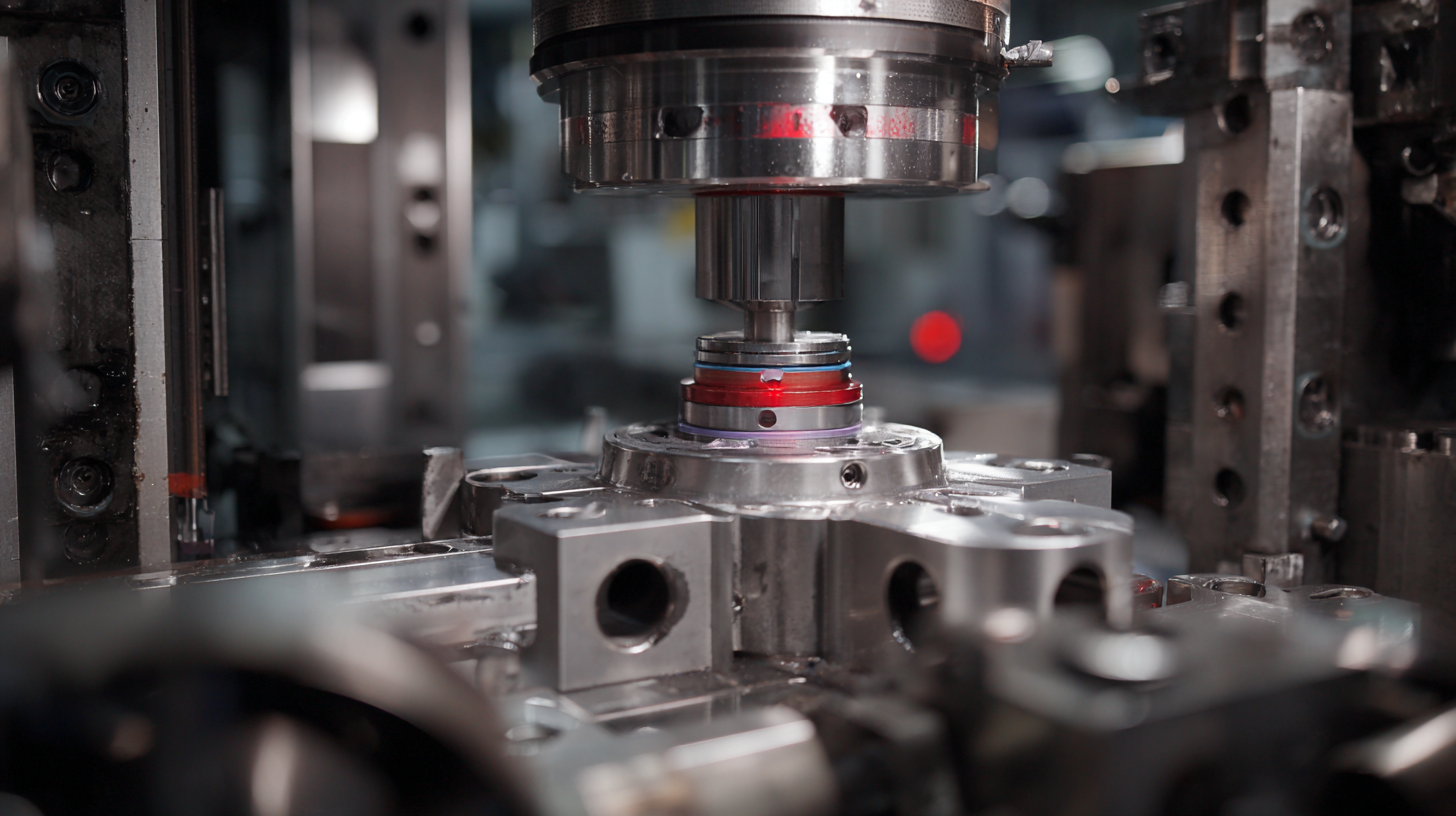

Analyzing Performance Metrics: Speed, Consistency, and Durability in Seal Machine Selection

When selecting a seal machine, performance metrics such as speed, consistency, and durability are crucial. According to a recent report by Smithers Pira, the global packaging market is projected to reach $1 trillion by 2024, underscoring the importance of efficient sealing processes. Speed is one of the primary factors; machines that can seal consistently at high rates—averaging around 20-40 packages per minute—are often preferred in high-volume production environments. This level of efficiency not only enhances productivity but also reduces labor costs.

Consistency is similarly vital, as variations in seal quality can lead to product spoilage and customer dissatisfaction. Data from a 2022 study published in the Journal of Packaging Technology indicates that seal integrity must exceed 95% for optimal performance in food packaging, where maintaining freshness is essential. Durable machines, designed to operate under heavy conditions, typically feature wear-resistant components that can withstand continuous use, further ensuring that production lines remain efficient without frequent downtimes. By thoroughly analyzing these performance metrics, businesses can make informed decisions that optimize their sealing operations and enhance overall productivity.

Comparative Cost Analysis: Budgeting for Seal Machines vs. Long-term Savings in Production

When considering a seal machine for your production needs, it’s essential to conduct a comparative cost analysis. Investing in a high-quality seal machine may initially seem more expensive, but the long-term savings can be significant. A well-engineered machine reduces the frequency of replacements and repairs, ensuring smoother operation and less downtime. These machines often provide superior sealing quality, enhancing your product’s shelf life and reducing waste.

Tips for budgeting include researching the total cost of ownership, which encompasses purchase price, maintenance, and operational costs. Additionally, consider the potential savings in labor costs due to increased efficiency and automation. It's also wise to reach out to manufacturers for quotes and explore financing options to spread the initial cost over time, making it easier to manage your budget.

To maximize your investment, look for seal machines that offer versatility and scalability based on your production growth. Opt for models that allow easy adjustment to accommodate various packaging sizes. This adaptability can help you avoid future costs associated with replacing or upgrading equipment as your production demands evolve. Investing wisely now can yield remarkable savings and efficiency in the long run.

Industry Standards and Certifications: Ensuring Compliance with Seal Machine Purchases

When selecting a seal machine, understanding industry standards and certifications is paramount to ensure compliance and optimal performance. The importance of adhering to these regulations cannot be overstated; according to a recent report by Packaging Strategies, around 70% of manufacturers have cited compliance with industry standards as a crucial factor in their purchasing decisions. Certifications such as ISO 9001, which focuses on quality management systems, and CE marking in Europe are essential for verifying that the machine meets safety and efficiency benchmarks.

In addition to these certifications, specific industry guidelines, such as those from the International Association of Packaging Professionals (IAPP), provide detailed insights into which features are necessary based on the application. For example, food packaging requires adherence to FDA regulations, which demand strict hygiene standards and the use of food-grade materials. A study by Freedonia Group shows that compliance-driven purchasers are increasingly favoring seal machines that integrate automated features designed to meet these stringent requirements, demonstrating that investments in compliant technology ultimately lead to enhanced operational safety and product integrity.

Comparison of Seal Machine Types Based on Industry Standards Compliance

Related Posts

-

The Ultimate Guide to Choosing the Perfect Seal Machine for Your Packaging Needs

-

Exploring Industry Growth: Vertical Form Fill Seal Machines at the 138th Canton Fair 2025

-

How to Optimize Your Production Line Using Stick Pack Machines for Maximum Efficiency

-

How to Choose the Right Form Fill and Seal Machine for Your Packaging Needs

-

How to Choose the Best Pouch Packaging Machine for Your Business Needs

-

The Ultimate Guide to Comparing Packaging Automation Solutions for Global Buyers